Home / All / Explosion Proof Devices / Flameless Venting, Flameless Explosion Venting, Flameless Explosion Vents, ATEX Protect for Dust Explosion

Categories

- Sinter-Plate Filter/Sinterlamellenfilter

- Cartridge Dust Collector

- Wet Dust Collector

- Cyclone Dust Separator

- Sinter-plate Dust Collector

- BIBO Filter Housing Unit

- Welding Fume Extractor

- Pharmaceutical Dust Collector

- HVAC Dust Collector

- Silo Bin Vent Dust Collector

- Powder Coating Dust Collector

- Laser Fume Extractor

- Centrifugal Fan

- Other Dust Collection Machine

- Baghouse/Bag Type Dust Collector

- Other HVAC Ventilation Equipments

- Pleated Dust Filters/Air Filters

- Explosion Proof Devices

- Vehicle Exhaust Hose Reels

- Keller Lufttechnik Type Dry Separator Dust Collector

Flameless Venting, Flameless Explosion Venting, Flameless Explosion Vents, ATEX Protect for Dust Explosion

Detail Information

Flameless Venting, Flameless Explosion Venting, Flameless Explosion Vents, ATEX Protect for Dust Explosion

Flameless vents provide the ultimate passive solution for applications when explosion venting is not possible.

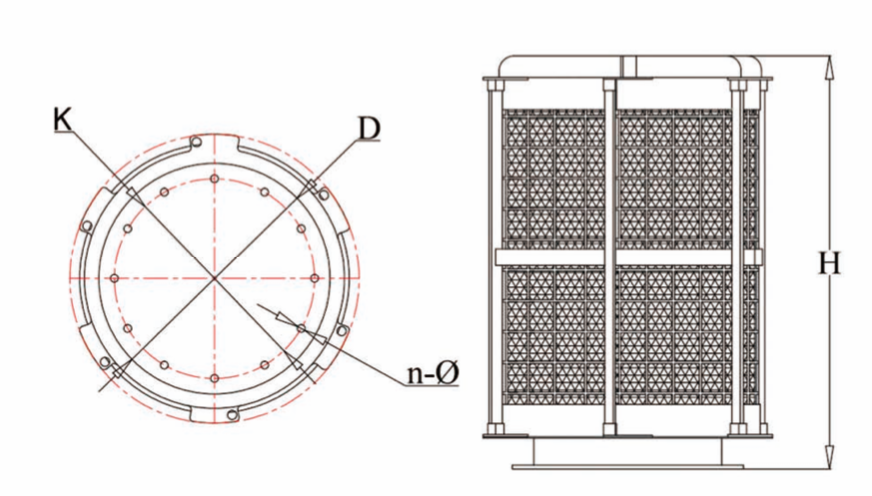

Flameless explosion venting devices is mainly composed of blasting disc and flameless discharge flame-extinguishing net. The device is installed on the protected equioment. When thedevice is innormal operation. The release plate is in a closed state. Once the dust explosion occurs in the device,the blasting disc opens instantly whenit reaches the blasting pressure range. The explosion pressure will leak from the crack of the flameextinauishinanet and the flame will pass through.The components of the flame extinauishing laver can quicklv cool the high-temperature flame to achieve quenching effect and nsure that the flame is not propagated, so as to prevent secondary or multiple explosions and protect the safety of equipment and personnel around it.

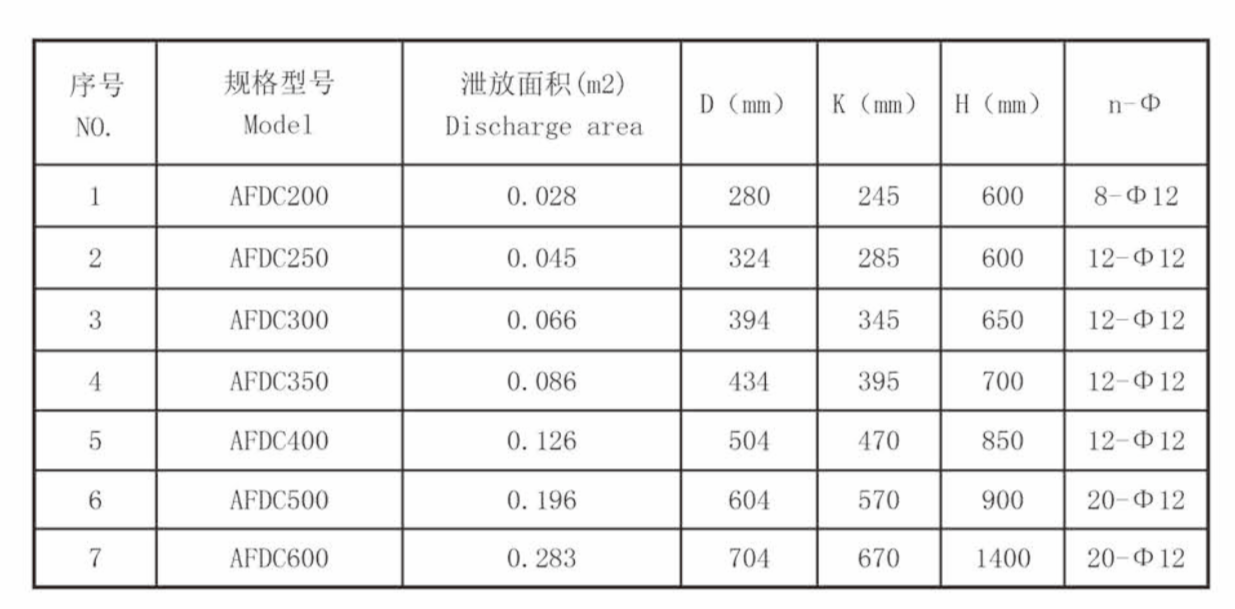

Technical Data

1: Product Form: Round;

2: Static Venting Pressure: 0.01MP±25%;

3: Max Release Pressure: 0.05MP;

4: Dust Type: Kst Less than 300Bargm3/s, St1 and St2 Dust;

5: Material: Carbon Steel or Stainless Steel;

6: Access Door, Easy Maintenance;

7: Meet EN16447-2014 standards;

8: Provide test report of third party authoritative institutions in China

Explosion Dust Examples:

1: Metal Industry: Magnesium, Titanium, Aluminium;

2: Coal Industry: Activated Carbon, Coal Dust;

3: Synthetic Material Industry: Plastics, Dye Dust;

4: Wood Industry: Paper Dust, Wood Dust;

5: Food Industry: Starch, Flour;

6: Agriculture: Cotton Dust, Tobacco Dust, Suger Dust;

7: Feed Industry: Blood Meal, Fish Meal.

Related Products

Please send your message to us

- Mobile Phone

- *Title

- *Content

subscription

NAVIGATION

Categories

- Sinter-Plate Filter/Sinterlamellenfilter

- Cartridge Dust Collector

- Wet Dust Collector

- Cyclone Dust Separator

- Sinter-plate Dust Collector

- BIBO Filter Housing Unit

- Welding Fume Extractor

- Pharmaceutical Dust Collector

- HVAC Dust Collector

- Silo Bin Vent Dust Collector

- Powder Coating Dust Collector

- Laser Fume Extractor

- Centrifugal Fan

- Other Dust Collection Machine

- Baghouse/Bag Type Dust Collector

- Other HVAC Ventilation Equipments

- Pleated Dust Filters/Air Filters

- Explosion Proof Devices

- Vehicle Exhaust Hose Reels

- Keller Lufttechnik Type Dry Separator Dust Collector

KEEP IN TOUCH

Please send your message to us

- Mobile Phone

- *Title

- *Content