Home / All / Pharmaceutical Dust Collector /

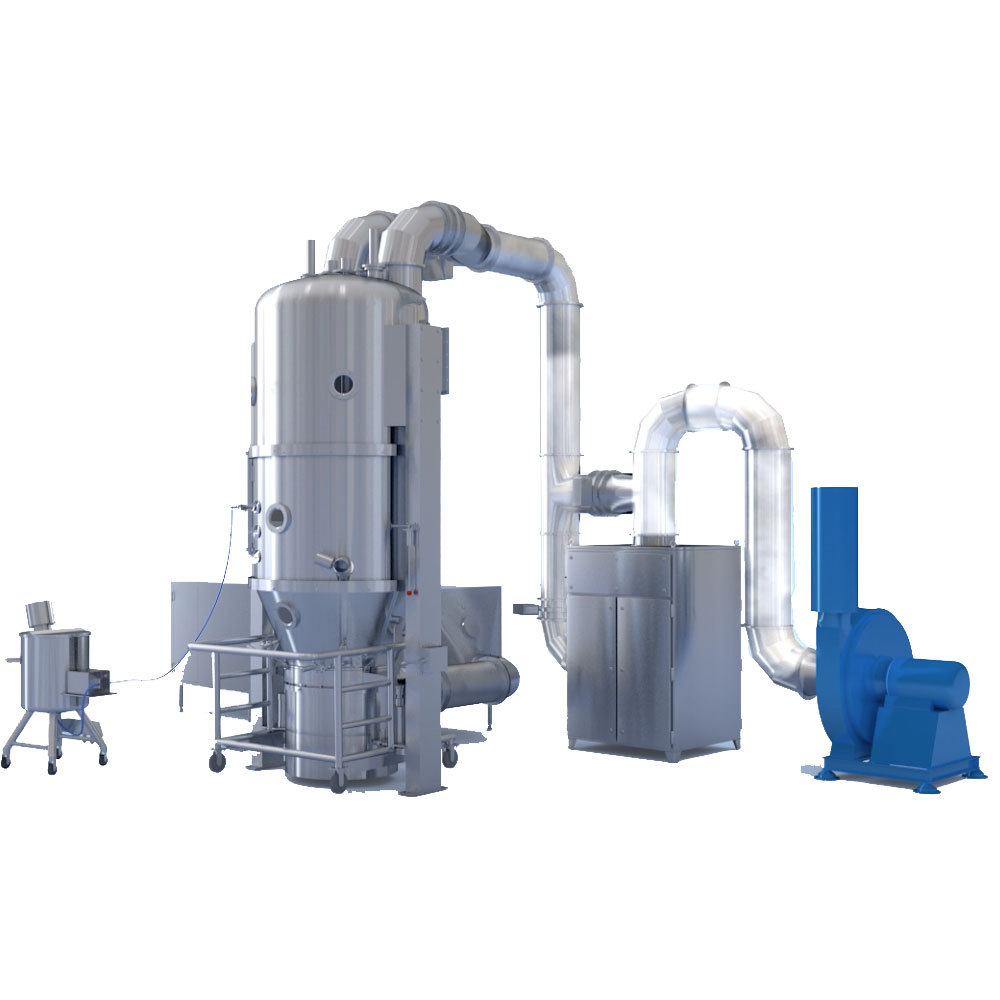

ACMAN FDB Fluidized Bed Dust Collector, Pharmaceutical Dust Extractor for Fluid-bed Granulator

Categories

- Sinter-Plate Filter/Sinterlamellenfilter

- Cartridge Dust Collector

- Wet Dust Collector

- Cyclone Dust Separator

- Sinter-plate Dust Collector

- BIBO Filter Housing Unit

- Welding Fume Extractor

- Pharmaceutical Dust Collector

- HVAC Dust Collector

- Silo Bin Vent Dust Collector

- Powder Coating Dust Collector

- Laser Fume Extractor

- Centrifugal Fan

- Other Dust Collection Machine

- Baghouse/Bag Type Dust Collector

- Other HVAC Ventilation Equipments

- Pleated Dust Filters/Air Filters

- Explosion Proof Devices

- Vehicle Exhaust Hose Reels

- Keller Lufttechnik Type Dry Separator Dust Collector

ACMAN FDB Fluidized Bed Dust Collector, Pharmaceutical Dust Extractor for Fluid-bed Granulator

| Categories | Pharmaceutical Dust Collector |

|---|---|

| Brand | ACMAN |

| Model | FDB-B-J |

| FOB port | NINGBO/SHANGHAI |

| Terms of Payment | T/T |

| Update Time | Apr 28,2025 |

Detail Information

ACMAN FDB Fluidized Bed Dust Collector, Pharmaceutical Dust Extractor for Fluid-bed Granulator

How Does the Dust Collector Working?

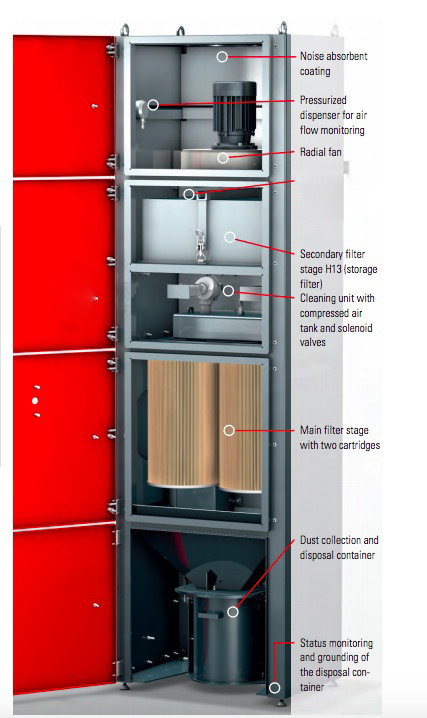

Dust Collection Unit Machine-Jet Type

Compact design make the dust collection machine unit so small, it consist of blower, second filter(HEPA) available, pulse-jet cleaning system, high efficiency cartridge filters, dust bin and control cabinet.

Upper Setting: Big airflow and high pressure centrifugal fan. full pressure is about 2000Pa, ACMAN also could OEM super high pressure blower as you needs.

Pulse-jet Backflow System:This dust extractor could cleaning the filters automatically, it need 0.4-0.6mp compressed air source. Helping by the pulse controller and solenoid valves, the back flow air could clean the dust on the surface of the cartridge filters. Then the filter will renewable.

Cartridge Filter Part:The filter chooses high efficiency polyester cartridge type, it has big filtration area than normal one. PTFE coating/Anti-flammable filters are available.

Secondary Filter Part Available:HEPA filter always act as a second filtration part to protect the environment in case the leakage of the first filtration part.

Bottom Setting: Dust Bin/Dust Drawer Available on different working conditions.

Advantages

1: Compact design(fan+jet system+filters+dust bin) saving lots of space for factories;

2: Larger filter areas than bag filter dust collector, because of its pleated cartridge filters;

3: Filters could renewable, the pulse-jet system keep the filters cleaning in a regular time;

4: Various of filter types, suitable for different working conditions;

5: Easy for maintenance: the filters are easy to change and only should remove dust regularly;

6: Less power consumptions: the centrifugal fan's design could provide high pressure and big airflow, the motor is E2 efficiency.

7: Air consumption is low: the compressed air consumption for pulse-jet is lower than baghouse;

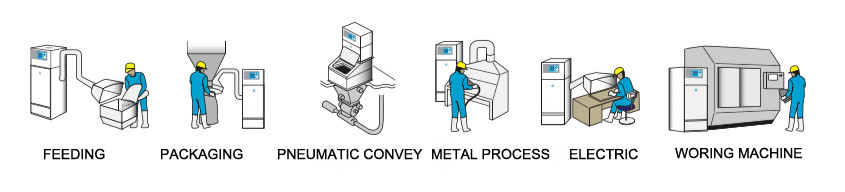

8: Wide applications: it can catch fine dust in most of industrials, and removes dust from pulverizing and grinding, crushing, sanding, powder injection and sealing, severing and cutting, stone and metal work, cutting work, substrate work and welding work... but moisture/sticky dust;

9: The efficiency is about F9 grade, if have HEPA secondary filtration, the efficiency is about H13;

10: Lower Noise, with sound proof sponge and centrifugal fan isolation box;

11: Material: 2mm SS400 carbon steel with powder coating or stainless steel SUS304.

Applications

Parameter

|

Model

(B) |

Airflow

(m³/h) |

Filter Area

(m3) |

Sustain

Pressure (Pa) |

Filters (mm) | Air Source (Mp) | 2nd HEPA |

FDB-35B-J | 2664-3405 | 35 | 12000 | 150*500-20 | 0.4-0.6 | Available |

FDB-60B-J | 4973-6457 | 60 | 12000 | 150*800-20 | 0.4-0.6 | Available |

|

FDB-80B-J |

7081-8489 |

75 |

12000 |

150*800-25 | 0.4-0.6 | Available |

|

FDB-100B-J |

8490-10455 |

94 |

12000 |

150*1000-25 | 0.4-0.6 | Available |

Customer Cases

Other Solutions

Related Products

Please send your message to us

- Tel

- *Title

- *Content

subscription

NAVIGATION

Categories

- Sinter-Plate Filter/Sinterlamellenfilter

- Cartridge Dust Collector

- Wet Dust Collector

- Cyclone Dust Separator

- Sinter-plate Dust Collector

- BIBO Filter Housing Unit

- Welding Fume Extractor

- Pharmaceutical Dust Collector

- HVAC Dust Collector

- Silo Bin Vent Dust Collector

- Powder Coating Dust Collector

- Laser Fume Extractor

- Centrifugal Fan

- Other Dust Collection Machine

- Baghouse/Bag Type Dust Collector

- Other HVAC Ventilation Equipments

- Pleated Dust Filters/Air Filters

- Explosion Proof Devices

- Vehicle Exhaust Hose Reels

- Keller Lufttechnik Type Dry Separator Dust Collector

KEEP IN TOUCH

Please send your message to us

- Tel

- *Title

- *Content