Home / Laser Cutting Dust Extraction Solution

Laser Cutting Dust Extraction Solution

Laser Cutting Dust Extraction Solution

Laser Fume Extractor is Necessary

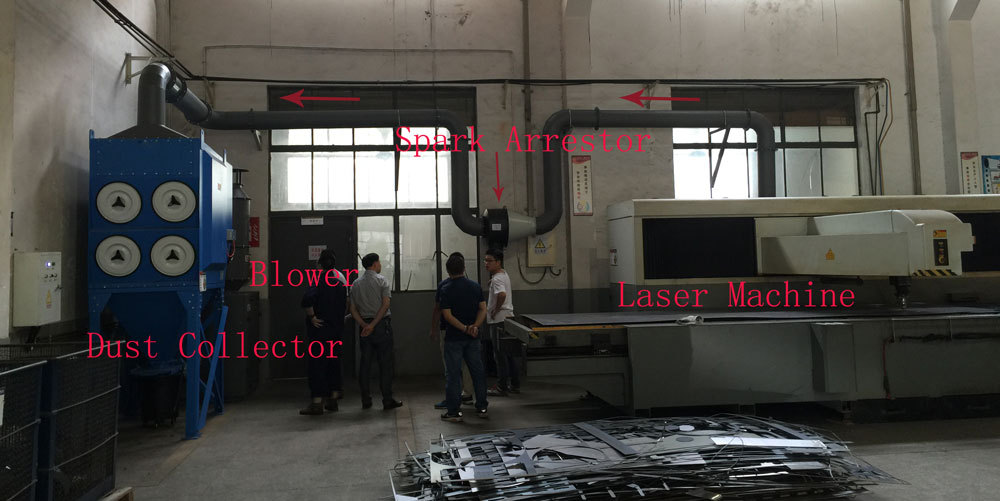

While laser cutting, the fume need to be extracted and purified, which could protect the workers health.

The fume could contain the sparks, and sharp components, so, we need to have a spark arrestor to first step process-catching the spark and other abrasive dusts to protect the second step filtration machine.

Normally, the airflow is from 6000-10000cbm depending on different types of laser cutters.

How to Choose your Suitable dust collector?

Airflow Calculation:

The air volume (unit: m³/h) of dust removal equipment is usually calculated based on the "cutting area" and "air change frequency":

- Air change frequency: Generally recommended 30~50 times/hour (high power or high dust materials need to be increased to 50~80 times).

- Calculation formula:

Air volume = table area (m²) × cutting height (m) × air change frequency (times/h)

*(The cutting height is usually estimated as 0.1~0.3m, the closed dust removal takes the lower value, and the open dust removal takes the higher value)

Other key factors

- Material type:

- When cutting metals such as stainless steel and aluminum, the dust particles are fine, requiring higher air volume (increase by 20%~30%) and explosion-proof measures.

- When cutting non-metals such as acrylic and wood, smoke treatment needs to be considered, and an additional filtration system may be required.

- Power and speed:

- For high power (≥6kW) or high-speed cutting, the air volume needs to be selected according to the upper limit.

- Dust removal method:

- Centralized dust removal: When multiple devices are shared, the air volume needs to be superimposed and the pipe resistance coefficient needs to be increased (1.2~1.5 times).

- Single-machine dust removal: Directly match the calculated value.

Precautions

- Insufficient air volume will cause dust to escape, affecting the health of workers and the life of equipment.

- The wind pressure (usually ≥2,000 Pa) needs to be matched to ensure suction, especially for metal dust.

- When consulting the supplier, provide parameters such as cutting material thickness, gas type (nitrogen/oxygen), working frequency** to optimize the selection.

It is recommended that the final solution be determined by a professional dust removal engineer based on the on-site working condition evaluation.

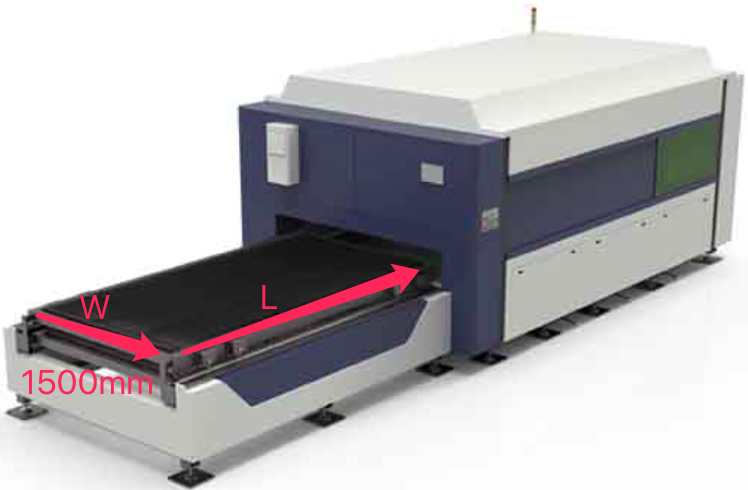

Size 1: Cutting Table Width 1.5m/59inch-Small and medium power optical fiber cutting machine

| Model | Width | Length | Square | Airflow | Dust Collector |

| 1530 | 1500mm/59inch | 3000mm/118inch | 4.5m2 | 3000m3/h | TOKA-30B-J |

| 1560 | 1500/59inch | 6000mm/236inch | 9m2 | 6000m3/h | TOKA-60B-J |

Dust Collector Technical Data

| Model | Airflow | Pressure | Filter Area | Power | Filter Material | Efficiency |

| TOKA-30B-J | 3000m3/h | 2500pa | 30 | 4kw | Anti-Flammable Polyester | 99.9%@1um |

| TOKA-60B-J | 6000m3/h | 2500pa | 48 | 7.5kw | Anti-Flammable Polyester | 99.9%@1um |

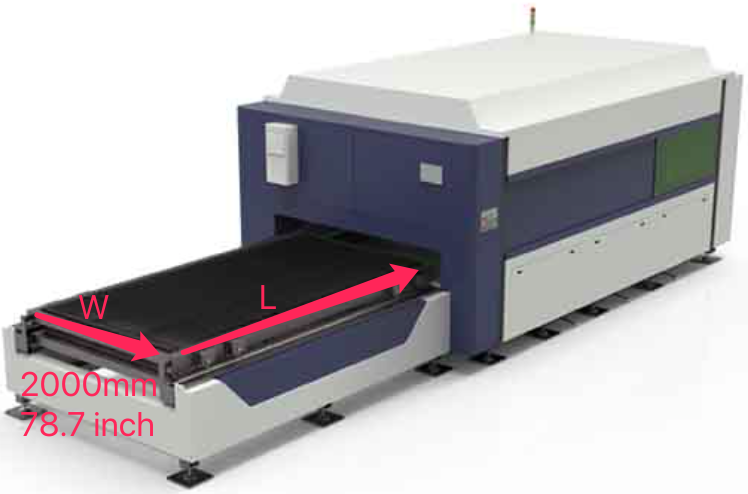

Size 2: Cutting Table Width 2m/78.7inch-Medium Power CO2/Fiber Cutter

| Model | Width | Length | Square | Airflow | Dust Collector |

| 2030 | 2000mm/78.7inch | 3000mm/118inch | 6m2 | 4000m3/h | TOKA-40B-J |

| 2040 | 2000/78.7inch | 4000mm/157.5inch | 8m2 | 6000m3/h | TOKA-60B-J |

| 2060 | 2000/ 78.7inch | 6000mm/236inch | 12m2 | 8000m3/h | TOKA-80B-J |

Dust Collector Technical Data

| Model | Airflow | Pressure | Filter Area | Power | Filter Material | Efficiency |

| TOKA-40B-J | 4000m3/h | 2500pa | 36m2 | 5.5kw | Anti-Flammable Polyester | 99.9%@1um |

| TOKA-60B-J | 6000m3/h | 2500pa | 48m2 | 7.5kw | Anti-Flammable Polyester | 99.9%@1um |

| TOKA-80B-J | 8000m3/h | 2500pa | 60m2 | 11kw | Anti-Flammable Polyester | 99.9%@1um |

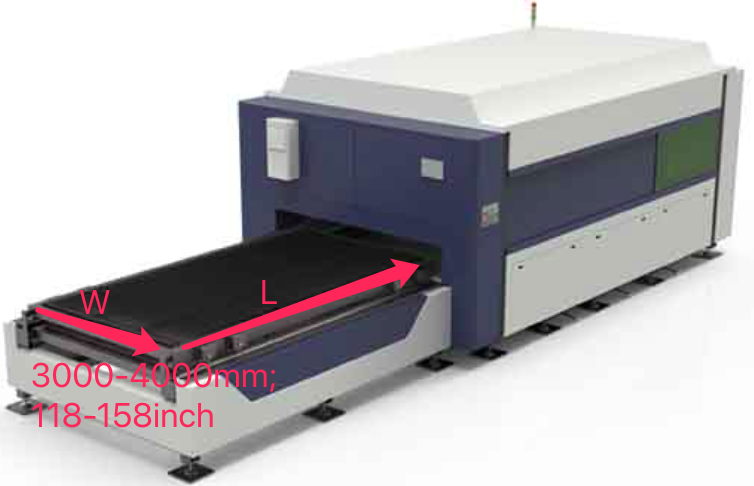

Size 3: Cutting Table Width 3m/118.1inch-4m/157.5inch-High power thick plate cutting machine/heavy duty plasma

| Model | Width | Length | Square | Airflow | Dust Collector |

| 3060 | 3000mm/118.1inch | 6000mm/236.2inch | 18m2 | 10000m3/h | TOKA-120B-J |

| 4080 | 4000/157.5inch | 8000mm/315inch | 32m2 | 21000m3/h | DFO-18 |

| | | | |||

Dust Collector Technical Data

| Model | Airflow | Pressure | Filter Area | Power | Filter Material | Efficiency |

| TOKA-120B-J | 10000m3/h | 2500pa | 90m2 | 15kw | Anti-Flammable Polyester | 99.9%@1um |

| DFO-18 | 21000m3/h | 3000pa | 180m2 | 22.5kw | Anti-Flammable Polyester | 99.9%@1um |

Normal process picture

Our Applications

Application in Russia Video

Our Cooperated Laser Company

- Dust Extraction Systems for Air Pollution Control

ACMAN is a passionate company whose mission is to provide clean air for industrial production processes with our creative filtration technology and sustainable dust extraction applications and solutions

subscription

Categories

- Sinter-Plate Filter/Sinterlamellenfilter

- Cartridge Dust Collector

- Wet Dust Collector

- Cyclone Dust Separator

- Sinter-plate Dust Collector

- BIBO Filter Housing Unit

- Welding Fume Extractor

- Pharmaceutical Dust Collector

- HVAC Dust Collector

- Silo Bin Vent Dust Collector

- Powder Coating Dust Collector

- Laser Fume Extractor

- Centrifugal Fan

- Other Dust Collection Machine

- Baghouse/Bag Type Dust Collector

- Other HVAC Ventilation Equipments

- Pleated Dust Filters/Air Filters

- Explosion Proof Devices

- Vehicle Exhaust Hose Reels

- Keller Lufttechnik Type Dry Separator Dust Collector

KEEP IN TOUCH

Please send your message to us

- Tel

- *Title

- *Content

- Upload

- Only supports .rar/.zip/.jpg/.png/.gif/.doc/.xls/.pdf, maximum 20MB.

Copyright © 2025 ACMAN ENVIRONMENT CO., LTD Support By BEE Cloud