Home / All / Industrial Dust Collector Inquiry / Current Situation and Development Trend of Air Purification Technology

Current Situation and Development Trend of Air Purification Technology

Current Situation and Development Trend of Air Purification Technology

In recent years, due to the development of science and technology and the progress of society, industrial emissions such as factories and automobiles have intensified the deterioration of air quality across the country, and severe weather has occurred frequently. In order to reduce energy consumption and improve the airtightness of the building, the ventilation volume in the building is reduced, and the indoor air environment is further deteriorated. Under this circumstance, people have begun to pay attention to the impact of gradually deteriorating air pollution on their own health and daily life. How to deal with and deal with this problem is a topic that must be studied and explored.

At present, the components and sources of indoor pollutants are mainly divided into three categories. The first type of pollutant is particulate matter, especially fine particulate matter led by PM2.5. Because of its extremely small diameter, it can even penetrate deep into human bronchioles and alveoli to deposit, which is extremely harmful to the human respiratory system. The main sources of particulate pollutants are exhaust emissions from automobiles and smoke from incomplete combustion of fuel, as well as kitchen fumes, cigarette smoke and pollutants released from building materials. The second type of pollutants are microorganisms, mainly including bacteria, molds and viruses that are harmful to the human body. Such air pollutants mainly come from damp and moldy walls, domestic garbage, pets, indoor flowers, carpets, and air conditioning filters in the room. Wait. The third type of pollutants are gas pollutants, which are mainly divided into organic pollutants and inorganic pollutants. Organic pollutants include various gas pollutants headed by TVOCs, including alkanes, aldehydes, esters and aromatic hydrocarbons. The main sources are building materials, cleaning agents, wax products, carpets, furniture, adhesives and paints, etc.; inorganic pollutants include carbon monoxide, nitrogen oxides, ammonia, ozone, hydrogen sulfide, radon, etc. The sources include construction, toilets, etc. Sewers, industrial and automotive exhaust, etc. Existing air purification technologies mainly deal with three types of particulate matter, microorganisms and gas pollutants.

The author introduces the single air purification technology applied in recent years and the principle of collaborative air purification technology with development potential, and summarizes the purification range, characteristics and development direction of various air purification technologies, and finally looks forward to the future air purification technology.

1 The principle of a single air purification technology

1.1 Fiber Filtration Technology

Fiber filters can be divided into coarse-efficiency filters, medium-efficiency filters, high-efficiency filters, sub-high-efficiency filters and high-efficiency filters according to filtration efficiency. The filter material of the coarse-efficiency filter is mainly wire mesh, coarse-pored cloth, foam plastic, etc. which are easy to clean and replace, and its filtration efficiency is evaluated based on particles with a particle size of 5 μm; The filter materials are mainly medium and fine-pored foam plastics, composite non-woven fabrics, glass fibers, etc., and the filtration efficiency is evaluated based on particles with a particle size of 1 μm; high-efficiency filters are similar to medium-efficiency filters; sub-high-efficiency filters are mainly Glass fiber filter paper, cotton short fiber filter paper, etc. are used, and the filtration efficiency is evaluated based on particles with a particle size of 0.5 μm; high-efficiency filter (HEPA) filter materials are mainly ultra-fine glass fiber paper, synthetic fiber paper and asbestos fiber paper. Filtration efficiency was evaluated based on particles with a particle size of 0.3 μm.

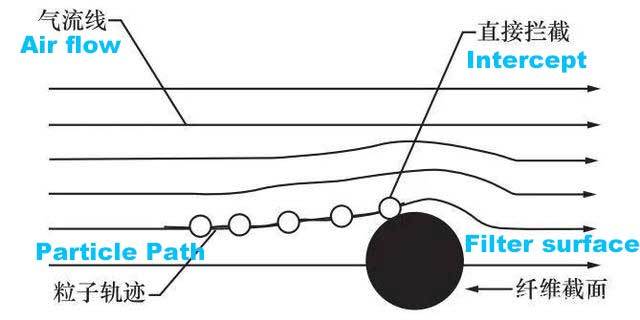

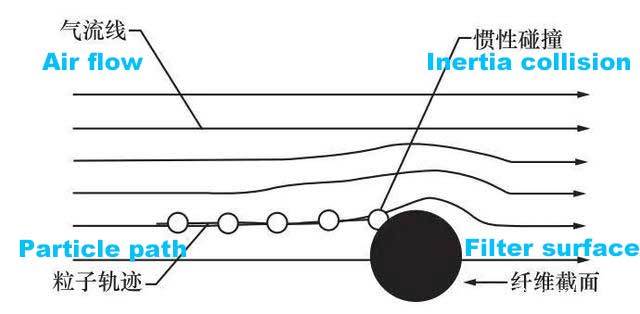

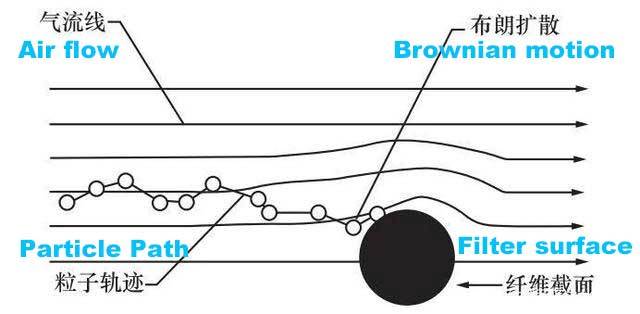

The polluted air passes through the fiber filter material, which is mainly affected by the interception effect, inertial collision, diffusion effect, gravity effect and electrostatic effect. The mechanism of action is as follows: the particles move along the streamline to the vicinity of the fiber surface, when the distance from the movement to the fiber surface is equal to or less than the particle radius, the particles will be intercepted by the fiber surface, which is the interception effect (see Figure 1); When the fiber layer passes through, during the violent turning process of the streamline, the particles break away from the streamline due to inertia and collide with the fibers and stay, that is, inertial collision (see Figure 2); for particles with smaller diameters, the Brownian motion is more intense, and this Irregular motion makes the particles have a greater chance of contacting and depositing on the surface of the fiber, that is, diffusion effect (see Figure 3); The electric charge can produce adsorption, and the particles are adsorbed to the fibers, that is, the electrostatic effect.

1.2 Activated carbon and similar materials

Adsorption is caused by the force between the adsorbent and the adsorbate molecules. This adsorption force can generally be divided into two categories: one is the interaction force between molecules caused by van der Waals force; the other is chemical bond force. , including electron transfer between solids and gases. These two forces exist at the same time, depending on which force is dominant. Physical adsorption is dominated by the van der Waals molecular interaction force, and the adsorbate is adsorbed on the surface of the adsorbent, which is a reversible process. Chemisorption relies on the chemical bond force between the solid surface and the adsorbed gas molecules, which is the result of chemical action, and its force far exceeds the van der Waals force of physical adsorption, which is often an irreversible process.

At present, the commonly used adsorption materials mainly include activated carbon, activated carbon fiber materials and related derivative materials (such as carbon nanotubes, graphene, etc.):

1) Activated carbon is one of the most common adsorption materials, and has a wide range of applications in industrial and daily fields. The raw materials for preparing activated carbon can be mainly divided into plants and minerals: plants include sawdust, coconut shell, walnut shell, etc.; minerals mainly include coal with various degrees of coalification, such as peat, lignite, bituminous coal, anthracite, etc.

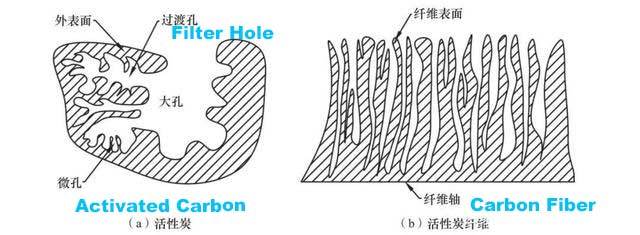

2) Activated carbon fiber materials have gradually attracted attention due to their better adsorption effect and better physical properties. Different from the structure of activated carbon, activated carbon fibers contain a large number of micropores that open directly on the surface of the fibers. The diffusion path of adsorbate to the adsorption site is shorter than that of activated carbon, and it has a larger surface area (1 000~3 000 m2/g), and the adsorption and desorption is very good. The attachment rate is fast and the adsorption capacity is large. In Figure 4, the left part is the microstructure of activated carbon, and the right side is the microstructure of activated carbon fiber.

3) Materials such as carbon nanofibers, carbon nanotubes and graphene are generally not used as the main material of adsorption filter elements in air purification applications due to material costs and other reasons, but are used in some special applications, such as gas sensors, for example A PAN carbon nanofiber/ZnO2/SnO2 composite material can be used as a gas sensor for nerve-like gas DMMP; some foreign scholars have made relevant discussions on the use of carbon nanotubes to prepare gas sensors and detect trace pollution gases; domestic scholars from Tsinghua University The application of such carbonaceous materials in air purification is also described more fully.

4) Adsorbents similar to activated carbon materials (such as activated alumina, silica gel and molecular sieves, etc.) are also widely used in industry. For example, gamma alumina is generally used for adsorbents, catalysts and catalyst carriers in petrochemical industries, and macroporous silica gel is generally used for catalyst carriers, matting agents, etc., and the most commonly used adsorbent in the field of air purification is activated carbon.

1.3 Electrostatic Precipitation

The principle of electrostatic precipitator technology is to use a high-voltage electric field to form a corona, and to pass the polluted air through the corona area, so that the particles in the polluted air are charged, and then under the action of the electric field force, they are adsorbed to the collection area with opposite polarity and deposited. , so as to achieve the effect of purifying particulate matter in the air.

The working principle of the commonly used electrostatic precipitator is shown in Figure 5. Generally, the polluted air will pass through a pre-filter to remove large particle pollutants and aerosols, and then pass through the ionization section and the dust collection section to finally obtain purified air.

The function of the ionization section is to charge the particles, and the charging process is divided into two stages: corona discharge and charging according to the sequence of the process. In the corona discharge area, because the air molecules will naturally radiate electrons, the electrons are accelerated to a high speed under the action of the electric field force and hit the air molecules, thereby generating positive ions and free electrons. This process is completed instantaneously in the ionization zone, and the free electrons will continue to hit the air molecules, forming a layer of electron cloud or positive ion cloud around the ionization wire.

After corona discharge, a large number of positive ions have been generated. The particles and positive ions are mixed together. Due to the Brownian motion of the positive ions, they will hit the particles, and the particles will be positively charged, which is diffusion charging. Diffusion charging does not require an electric field and is independent of the type of particle. As the positive charge on the particle increases, the particle creates an electric field that repels other positive ions, thereby weakening subsequent impacts. When the charge on the particle increases to a certain level, no positive ions can overcome the repulsive force to hit the particle, and the charge ends.

The positively charged aerosol particles enter the dust collecting section with the air, are adsorbed by the electric field force, and are adsorbed on the dust collecting plate, thus completing the electrostatic dust removal work.

1.4 Low temperature plasma

Low-temperature plasma is a partially ionized gas that can be generated by applying a high-voltage discharge between two electrodes. It is rich in charged particles, high-energy electrons, and active particles, such as free radicals, excited atoms and molecules. Atoms or molecules in excited states generate various light radiations during electronic transitions. Plasma is generated by high-voltage discharge, and these chemical effects are accompanied by physical effects such as strong electromagnetic fields, thermal effects, and shock waves. Such physical and chemical characteristics can generate huge energy to break chemical bonds and do many complex chemical reactions. Low-temperature plasma shows that it can quickly and efficiently sterilize and deal with complex pollution.

There are many methods for generating low temperature plasma, the common ones are electron beam radiation method, low pressure glow discharge method, dielectric barrier discharge method, pulse corona discharge method, DC corona discharge method and so on. The discharge will generate a large number of high-energy electrons and ions to bombard VOCs molecules, and through a series of complex chemical reactions, the pollutant molecules will be decomposed, which can theoretically be finally degraded into harmless products such as CO2 and H2O.

1.5 Photocatalytic Technology

At present, the commonly used photocatalysts are mainly semiconductor materials represented by TiO2. Taking TiO2 as an example to introduce the principle of photocatalytic air purification technology: when light waves greater than or equal to 3.2 eV (wavelength less than 380 nm) are irradiated on the surface of TiO2, some valence band electrons absorb energy and undergo energy level transitions, and the electrons transition to the conduction band Then, a hole will be generated in the valence band accordingly, thereby forming an electron-hole pair. At this time, the electrons on the conduction band can be used as reducing agents because of their higher energy, and the holes with lower energy can be used as oxidants. When the electron-hole pair has a long enough existence time, it can undergo a redox reaction with the VOCs pollutants adsorbed on the surface of TiO2, so as to achieve the purpose of degrading the pollutants. If nano-TiO2 particles are used, due to the quantum size effect of ultra-fine particles, the photocatalytic activity of the catalyst can be improved. At the same time, the nano-sized particles are small, the surface atoms are many, and the specific surface area is large, and the ability of the photocatalyst to adsorb organic substances is enhanced. The oxidative decomposition of pollutants is more sufficient and effective.

The specific reaction of the degradation is described as follows. The holes act as a strong oxidant to oxidize the hydroxyl groups (OH-) and water (H2O) adsorbed on the surface of TiO2 to hydroxyl radicals ( OH), while the conduction band electrons act as a strong reducing agent, which will be absorbed by the TiO2 surface. The dissolved oxygen adsorbed on the surface of TiO2 is captured to form superoxide anion radicals (O-2); some superoxide anion radicals (O-2) can continue to generate hydroxyl radicals (·OH) through chain reaction. The generated superoxide anion free radicals and hydroxyl free radicals have strong oxidizing properties, which can attack the unsaturated bonds of pollutants, or extract hydrogen atoms to generate new free radicals, stimulate chain reactions, oxidize them, and finally cause pollutants. Degrades into harmless substances.

1.6 Other purification technologies

There are also some purification technologies, which have low market application rate and little research value due to large defects or narrow scope of application. For example, the principle of negative ion technology is similar to that of plasma and electrostatic precipitator, but it has the defect of high ozone generation, and it has almost no purification effect on gas pollutants; ultraviolet technology and ozone technology only have good effects on sterilization, and have good effects on particulate matter and gas pollution. Things are powerless; water washing is effective for some gas pollutants that are easily soluble in water, but there are problems such as high air humidity and few types of pollutants.

In addition, there is a special kind of purification technology - ozone purification technology. Since technologies such as electrostatic precipitator will produce ozone as a by-product, it is generally necessary to use an ozone purification module when using this type of technology, that is, to eliminate ozone through a catalyst to achieve the effect of purification.

2 Introduction of synergistic air purification technology

The synergistic technology of air purification generally refers to a type of composite technology in which two or more purification technologies combine and promote each other. Different purification technologies can play a synergistic role due to the complementarity of purification mechanisms, and generally have better purification efficiency than the original single technology, so they have strong research value. At present, the more common synergistic technologies include adsorption-photocatalysis technology and low-temperature plasma-photocatalysis technology.

2.1 Adsorption-photocatalysis technology

Adsorbent materials such as activated carbon have the advantages of strong adsorption of low-concentration pollutants, but at the same time they have the disadvantage that they can only enrich and cannot degrade pollutants and need to be replaced regularly. However, photocatalytic technology is limited by the problem of reaction contact area and cannot be used for low-concentration pollutants. Contaminants are rapidly degraded. The advantages and disadvantages of the two can be complementary. The adsorption principle is used to enrich the pollutants on the surface of the adsorption material, and then the pollutants are degraded by catalytic technology, which avoids the disadvantage that the adsorption material cannot degrade the pollutants and needs to be replaced regularly. , and avoids the problem that the electrocatalytic technology has a slow rate of treating low-concentration pollutants.

In 1997, a Japanese scholar proposed a composite material in which photocatalyst TiO2 was attached to activated carbon particles. After that, some researchers expounded the mechanism of the mutual enhancement of the purification ability of photocatalysts and activated carbon, and prepared different purification materials through different methods and raw materials. For example, a thin layer of TiO2 was formed on the activated carbon carrier by dip coating, and an activated carbon-nano-TiO2 composite photocatalytic air purification net was developed; a Fe-TiO2-zeolite composite material was prepared by a sol-gel method, which was verified by tests. It has high removal efficiency of formaldehyde under visible light; a series of TiO2-molecular sieve/corrugated ceramic fiber composite photocatalyst materials were prepared by dipping and calcination method, and the optimal molecular sieve loading was verified; electrospun nanofiber membrane was used as the Attachment, electrospray technology is used to deposit photocatalyst and activated carbon on the surface of fiber, and further composite multilayer film is obtained by electrospinning technology.

2.2 Low temperature plasma-photocatalytic technology

Both plasma technology and photocatalytic technology are mainly aimed at purifying gaseous pollutants (such as VOCs, etc.) in the air, and the combination of the two can play a role in promoting each other. Experimental studies have compared the purification effects of the two technologies synergistically, low-temperature plasma alone, and photocatalytic technology alone on pollutant formaldehyde.

There are many types of low-temperature plasma-photocatalytic coupled reactors currently used for air purification. According to the discharge form, it can be divided into dielectric barrier discharge reactor, creeping discharge reactor, pulse corona discharge reactor, etc. According to the electrode structure, it can be divided into needle plate type, wire plate type, flat plate type, bobbin type, etc. According to the different placement positions of the photocatalyst in the reactor, that is, in the discharge region (in-plasma catalysis, IPC) and the afterglow region (post plasma catalysis, PPC), the reaction system can be divided into two categories. According to this, some researchers refer to them as single-stage plasma catalysis (SPC) and two-stage plasma catalysis (TPC) or plasma-driven catalysis. catalysis, PDC) and plasma-assisted catalysis (plasma-assisted catalysis, PAC. At present, there are many researches on PPC technology. Starting from the principle of low-temperature plasma-photocatalysis technology, it is believed that the catalyst can form a more obvious synergistic effect in the discharge region. A large number of active ions, electrons, free radicals, etc. generated by the plasma generator can, on the one hand, stimulate the particles to transition downward with high energy to generate ultraviolet light, and activate the photocatalyst to produce a catalytic reaction. On the other hand, the plasma discharge has a direct activation effect on the photocatalyst, which can enhance the Its catalytic performance. In addition, the combined action of the two is conducive to the deep reaction of the by-products generated by the reaction, so that they can be completely degraded into harmless products such as H2O and CO2, which effectively improves the degradation efficiency.

3 Air purification technology purification range and advantages and disadvantages

Each air purification technology has its applicable purification range, advantages and disadvantages. When applying purification technology, it is necessary to reasonably consider the characteristics of different purification technologies, make full use of strengths and avoid weaknesses, and play its due role. The following is a brief description and summary of the purification range and characteristics of various purification technologies:

1) Fiber filtration technology has a good filtering effect on particulate matter. Since microorganisms such as bacteria and viruses are generally attached to suspended particulate matter, it also has a filtering effect on microorganisms, but it has little effect on gas pollutants. Its advantages lie in mature industrial production, safe use, convenient maintenance, and extremely high filtering effect on particulate matter. The disadvantage is that it belongs to non-renewable consumables and needs to be replaced regularly, and it is easy to cause secondary pollution of adsorbed microorganisms in an environment with high humidity. Especially when used in places with serious pollution, its service life is shorter and the maintenance cost is higher. In addition, the high-efficiency filter has a large wind resistance, which requires high static pressure and noise control of the fan.

2) Activated carbon adsorption technology has adsorption effect on pollutants, but particulate matter is easy to block the micropores of activated carbon, so that the adsorption force quickly fails, and microorganisms are easy to enrich and reproduce on the adsorption matrix, resulting in secondary pollution, so it is generally used for gas pollutants. purification. Its advantages are that it has a broad spectrum of adsorption capacity, has a certain purification efficiency for almost all gas pollutants, and is the same as the fiber filter, which is safe to use, easy to maintain, and has a large adsorption capacity. It is the most widely used purification material. The disadvantage is that there is a limitation of adsorption capacity, which needs to be replaced regularly, and due to its non-targeted adsorption, it also has adsorption effect on harmless substances in the air (such as water vapor, etc.), which will lead to a decrease in its effective adsorption capacity; no degradation of adsorbed pollutants It is easy to breed microorganisms in a wet environment, causing secondary pollution.

3) Electrostatic dust removal technology is mainly used for the purification of various particulate matter, and because the generated charged ions and ozone can effectively destroy the biological structure of bacteria and viruses, it has a good microbial purification effect, but it has almost no effect on gas pollutants. . Its advantages are that compared with high-efficiency fiber filters, the wind resistance is smaller, the filter material is not consumed, the dust collecting board is easy to clean and can be reused, and the sterilization ability is strong, which will not cause secondary pollution. The disadvantage is that the principle of the equipment is complex, there is a high-voltage area, and the maintenance is highly specialized; it is greatly affected by factors such as ambient temperature, humidity and dust specific resistance, and cannot maintain a high purification efficiency; although the generated ozone has a bactericidal effect, it is necessary to prevent In a closed environment, the increased ozone concentration is harmful to human health.

4) The application of low-temperature plasma technology in the field of air purification has its unique advantages. The use of high-voltage discharge reaction can degrade VOCs without frequent replacement and low secondary pollution. In addition, the generated high-energy particles, ozone and ultraviolet rays can all play a role in sterilization. However, in actual engineering, there are some problems if the low-temperature plasma technology is used alone. The higher the plasma power, the higher the degradation efficiency of VOCs, but the more toxic by-products. Degradation efficiency will decrease. Low-temperature plasma technology is also less effective for the degradation of inorganic pollutants such as nitrogen oxides. It is also worth mentioning that because the discharge area is filled with a large number of high-energy electrons and ions, as well as by-products such as ozone, it also has a strong killing effect on microorganisms such as bacteria and viruses in the air.

5) Photocatalytic technology has development potential in the field of air purification. It reacts at room temperature and pressure, has low energy consumption, and is more energy-saving and safe than low-temperature plasma technology; as a type of catalytic reaction, it can degrade VOCs quickly, effectively and renewable. It does not need to be replaced as frequently as activated carbon; the material has strong plasticity and is easy to use, such as all kinds of tile coatings can be applied. Relevant studies have shown that TiO2 photocatalyst can not only degrade toxic compounds produced by harmful microorganisms, but also directly act on the biological macromolecules of bacteria and viruses to promote their destruction and decomposition to achieve sterilization. However, in the process of research, it was found that the photocatalytic technology represented by TiO2 currently has defects that hinder its industrial application. TiO2 has better catalytic activity mainly at ultraviolet wavelengths and lower efficiency at visible light wavelengths, which may require additional ultraviolet lamps to promote photocatalysis in practical applications. Aromatic VOCs have a low reaction rate under the photocatalysis of TiO2 and can lead to catalyst deactivation. In practical applications, photocatalytic treatment is limited by many factors and the degradation rate is slow. In addition, the incomplete photocatalytic reaction may produce toxic intermediates such as acetaldehyde. For inorganic pollutants such as oxides with relatively stable chemical bonds and radon, the degradation effect of photocatalytic technology is very limited.

4 Development direction of air purification technology

1) The fiber filtration technology represented by HEPA is a commonly used particle purification technology, and its market application is very mature. At present, the main development directions are various, mainly reflected in the development of high-fiber nano-molecular materials represented by electrospinning, and the expansion research on this basis. For example, gradient composite filter materials with different densities and pores can filter particles of different diameters in layers to improve filtration efficiency; fuse or coat various catalytic materials, so that fibers have certain sterilization ability or gas pollutant purification function. In addition, there is another type of electret filter material worth mentioning. Electret refers to a dielectric material with a long-term charge storage function. It has the characteristics of being able to generate electrostatic force by itself in the absence of an external electric field. Directly relying on electrostatic force to directly attract charged particles in the air and capture them, or induce neutral particles in the air to generate polarity and then capture them, compared with conventional materials, it has the characteristics of high filtration efficiency and low resistance.

2) Activated carbon adsorption technology is one of the most commonly used purification technologies for gas pollutant purification. There are three main development directions: the first is to make new breakthroughs in adsorption strength and adsorption capacity by developing new adsorption materials; Targeted modification treatments such as surface impregnation or halogenation make it characterized by strong adsorption of target gas pollutants; the last one is synergistic with photocatalytic technology, using activated carbon to adsorb and enrich pollutants , to promote the photocatalytic reaction, and achieve a benign purification cycle of adsorption-degradation-adsorption.

3) Electrostatic precipitator technology is one of the commonly used particle purification technologies, which has unique advantages compared to HEPA. In practical applications, the main defect that limits its application is that it will generate ozone and cause secondary pollution. Its main development directions: First, by studying the principle of discharge, improving the discharge equipment and reducing the amount of ozone released. For example, the ozone generation rate is related to voltage and discharge structure, and is affected by temperature, and the ozone generation concentration is reduced by technologies such as corona wire heating. The second direction is to achieve the purpose of ozone purification through the coupling of ozone elimination technology and electrostatic dust removal. Some researchers have summarized and compared the methods of controlling ozone concentration. Generally, the methods of eliminating ozone include heating, adsorption, and catalytic reaction. However, both heating and adsorption have various defects, while the catalytic decomposition method has high decomposition rate and long validity period. And other advantages, there is a greater potential for development. For example, the combination of photocatalytic technology and high-voltage static electricity can not only eliminate ozone but also complete the removal of pollutants such as VOCs.

4) Plasma purification technology is another kind of potential purification technology. For some complex application environments, such as ship cabins, due to the narrow space, dense personnel and equipment, and insufficient endurance of adsorbent materials, plasma purification technology with strong degradation ability is suitable. The theoretical reaction of plasma purification technology is complex, and the influencing factors are diverse, so it has strong research value. Its development direction: one is to improve the degradation efficiency through rational design of generating equipment; the other is to couple with various catalysts, such as adsorbents, metal catalysts and photocatalysts, etc., the purpose is to improve the degradation efficiency of pollutants.

Photocatalytic technology is limited by factors such as catalyst contact area, surface wind speed and pollutant concentration, and its purification efficiency is poor when used alone. However, its material has strong plasticity and mild catalytic conditions, and is suitable for use in synergistic coupling with other gas purification technologies.

There are three main research directions in adsorption-photocatalysis technology research: First, the selection of catalyst types. At present, for indoor air purification, most of the research still uses TiO2 with broad spectrum purification ability as the test object, and a small amount of other catalyst types and purification methods are used. The second is the selection of adsorbents, which are generally still based on conventional adsorbent materials, such as activated carbon, activated carbon fibers, zeolite, molecular sieves, etc. There are some ceramic carriers and metal-organic frameworks (MOFs), etc.; the third is the way of compounding the two. Taking activated carbon and TiO2 as an example, there are mainly mechanical mixing, carbon dispersed in TiO2 bulk, carbon-coated TiO2 particles, etc., and TiO2 in TiO2. Load on activated carbon. The loading of TiO2 on activated carbon is the most common, and its preparation methods mainly include direct dip coating method, sol-gel method, sputtering method, direct hydrolysis method, solution method, chemical vapor deposition method, etc.

The research on low-temperature plasma-photocatalysis technology is still immature and still in the laboratory research stage. Most of the current research on VOCs degradation reactors only selects a specific organic waste gas, and then studies its degradation characteristics under a specific power supply and reactor. The conclusions about the discharge form and reactor structure are often only applicable to the researched exhaust gas or specific applications. Therefore, it is necessary to further optimize the structure of the discharge power source and the reactor, and explore the matching method with general guiding significance between the two. At present, there are many factors that affect the synergistic photocatalytic purification of VOCs by low-temperature plasma, including the structure and parameters of the ion reactor, and the different types of VOCs and catalysts, which all affect the purification efficiency. Therefore, it is necessary to study the purification reaction more systematically, and it is necessary to expand the technology for processing various types of VOCs so as to be closer to practical applications. It is also necessary to analyze the factors affecting purification, and to promote the research and development of reactor structural parameters and new catalysts. Further improve the purification efficiency.

subscription

NAVIGATION

Categories

- Sinter-Plate Filter/Sinterlamellenfilter

- Cartridge Dust Collector

- Wet Dust Collector

- Cyclone Dust Separator

- Sinter-plate Dust Collector

- BIBO Filter Housing Unit

- Welding Fume Extractor

- Pharmaceutical Dust Collector

- HVAC Dust Collector

- Silo Bin Vent Dust Collector

- Powder Coating Dust Collector

- Laser Fume Extractor

- Centrifugal Fan

- Other Dust Collection Machine

- Baghouse/Bag Type Dust Collector

- Other HVAC Ventilation Equipments

- Pleated Dust Filters/Air Filters

- Explosion Proof Devices

- Vehicle Exhaust Hose Reels

- Keller Lufttechnik Type Dry Separator Dust Collector

KEEP IN TOUCH

Please send your message to us

- Mobile Phone

- *Title

- *Content